Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

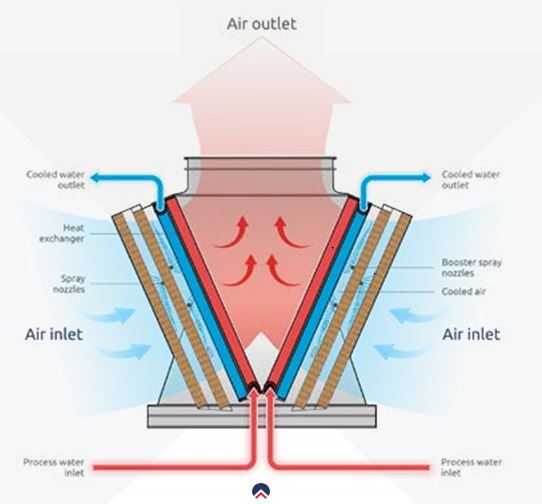

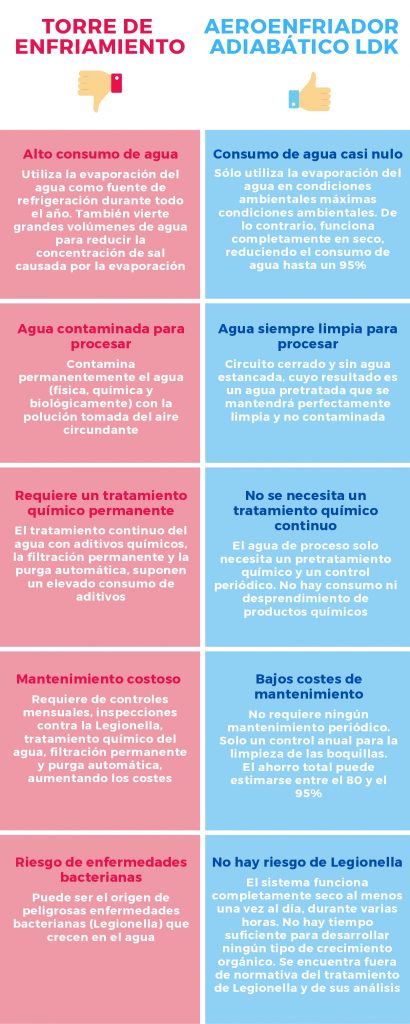

Consume up to 95% less water and save up to 95% on maintenance costs

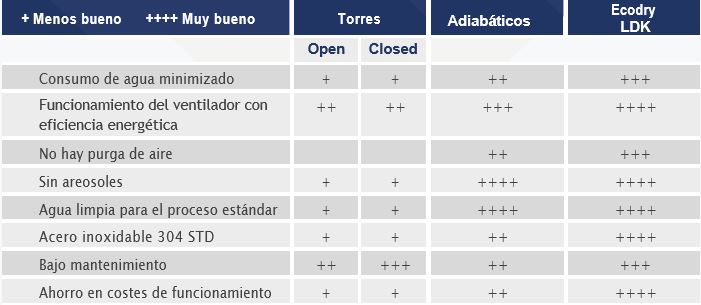

Every drop of water as well as every kW of electricity saved makes a difference. We have used our extensive experience to create the LDK adiabatic dry cooler, adding new features requested by the market. Thanks to the precise control of our units, your energy consumption is kept to a minimum, and With our modular configuration, we can cover a capacity range from 400 to 2,800 kW.

Industrial design and execution for the refrigeration of medium and heavy loads. In addition, our patented solutions will keep your carbon footprint and water consumption low.

It has 3 working modes:

Dry operation in cold or intermediate seasons. Outside air is led directly to the heat exchanger. The CoolPad system is deactivated in the free air intake position. The air flow is modulated depending on the temperature. The result is energy and water savings.

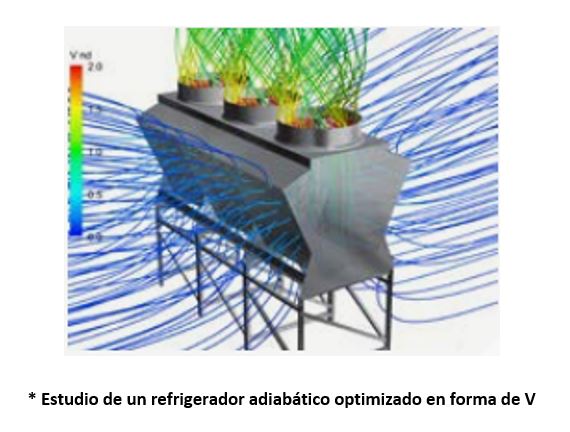

Adiabatic system in hot season. Outside air passes through the CoolPad. Here the definitive design of the patented CoolPad provides the best humidification and cooling of the air: the efficiency increases overall performance.

Only in extremely high weather conditions, when the adiabatic mode is not enough to keep the outlet water temperature within a predefined set point, the boost mode is activated automatically entering hybrid functionality.

Integrated refrigeration systems are synchronized with the processing lines

This means that your consumption follows the actual demand: i.e. if a production line stops, the cooling system also stops, saving energy and money while the rest of the factory continues. When demand drops and production needs to decrease, synchronous cooling works accordingly, using less energy as a result.

We explain more about the Ecodry LDK in the following video:

As can be seen in the images, both units contain the panels that will collect the water to later proceed to carry out the corresponding cooling process. The difference is that: the conventional equipment requires much more water because it works by completely soaking it by injection, and then all that water is lost. While the Ecodry system, through its patented adiabatic chamber, carries out a nebulization process to humidify both the air and the panels in parallel, thus optimizing water consumption.

For this reason the Ecodry LDK is unique in the market, being the most ecological and sustainable adiabatic cooler that currently exists, saving not only 95% of water, but also reducing CO2 by up to 40%, as well as operating costs. and maintenance, thanks to its technology patented exclusively by the Frigel Group.

You want to know more?

¿Por qué Vacca Engineering?

Nos encargamos del asesoramiento técnico, diseño, ejecución, legalización y mantenimiento

Solicita Información

Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

© Vacca Engineering 2020 | Aviso legal | Política de cookies